Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

ブランド: DoHform

原産地: 中国

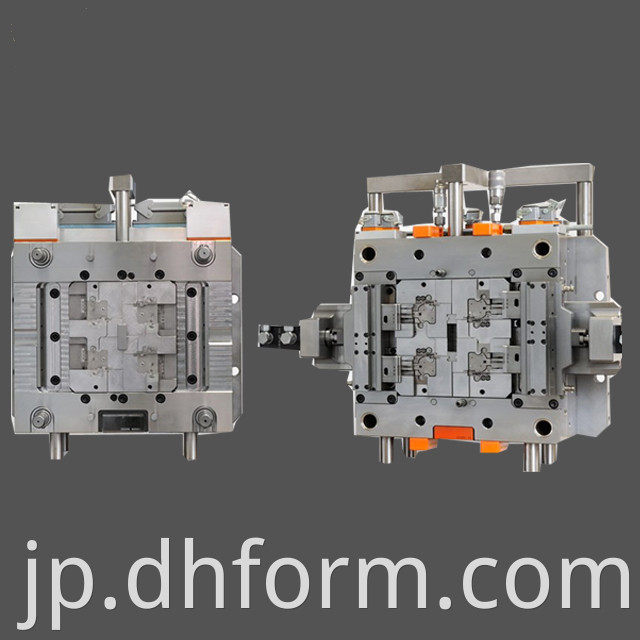

形成方法: プラスチック射出型

製品資料: ゴム, プラスチック

製品: 車両型, 家電, 家庭用品

包装: 標準輸出木箱梱包、燻蒸工程(必要に応じて)

輸送方法: Ocean,Land,Air

原産地: 昆山、中国

ポート: Shanghai,Ningbo,China

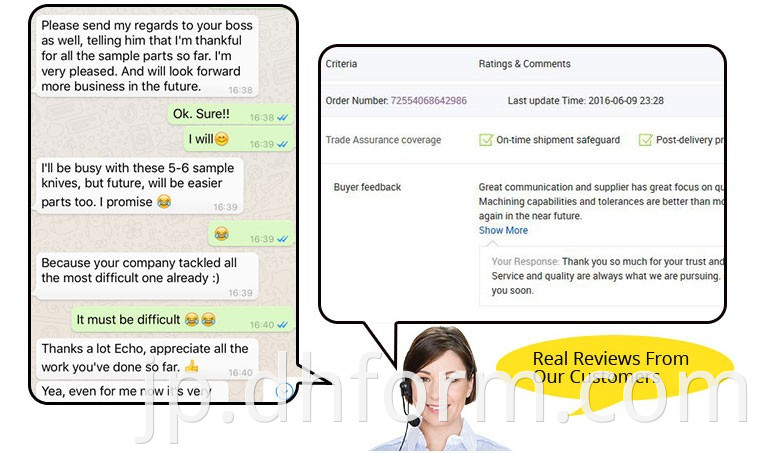

お支払い方法の種類: L/C,T/T,Western Union

インコタームズ: FOB,CFR,CIF,EXW

電気デジタルプラスチック部品成形

電子製品/自動車製品のための中国工場のプラスチック射出工具

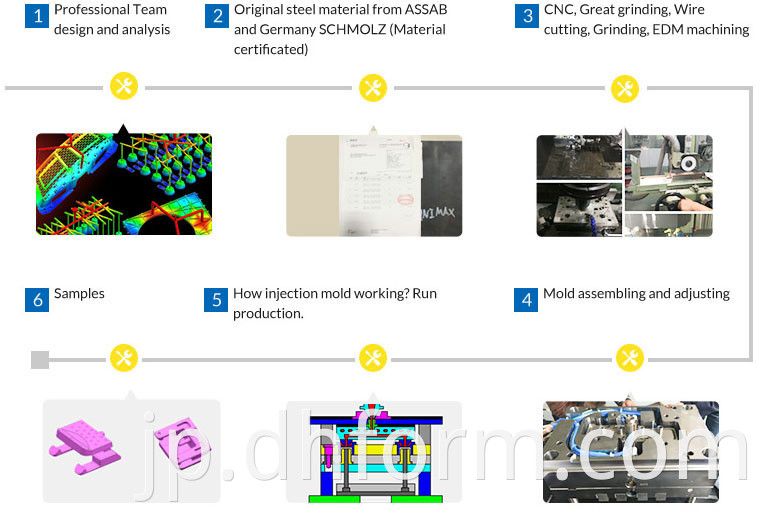

1.部品設計分析から始めます。

2.金型設計図とDFMレポートが利用可能であるため、金型を作成する前に金型がどのようになるかを確認できます。

3.製品が複雑な場合は、モールドフローレポートも表示されます。

4.屋内ワークショップは、適切な管理の下で高品質を保証します。

5.通常、型を作るのに15〜60日かかります。正確な時間は、設計の複雑さによって異なります。

|

Product name |

Plastic injection molded parts for electrical components |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

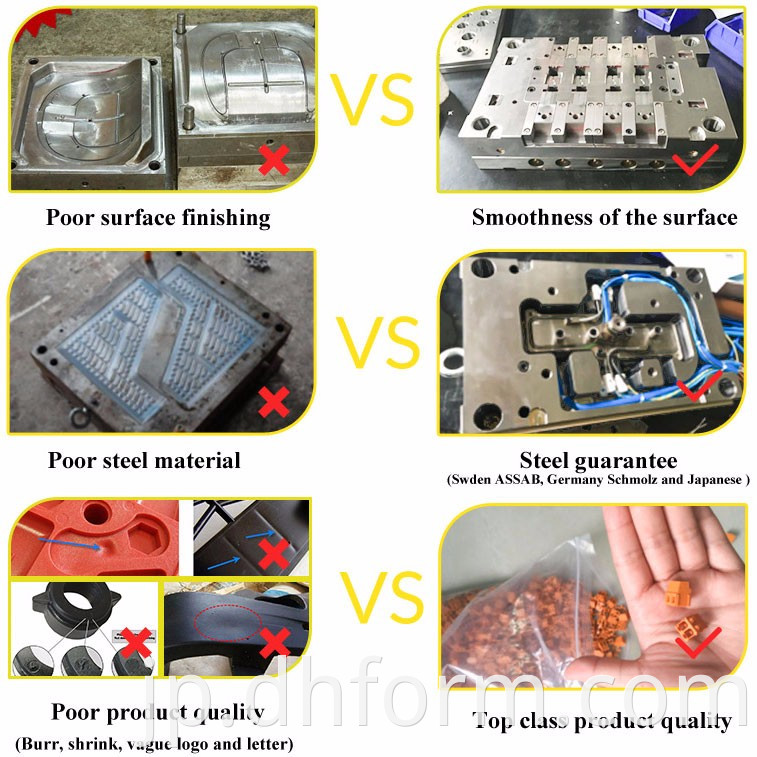

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: SCHMOLZ: P20HH, 2738, 2083H,2343, 2344, etc. DIN: 1.2738,1.2083, 1.2343, 1.2344, 1.3343, etc. AISI: P20, H13, D2, D6, M2, etc. ASSAB: 718HH, Nimax, 8402, 8407, XW-10, XW-5, EM2, etc. Japanese: HPM2, NAK80, SKD61, SKS3, SKD11, DC53, SKH51, etc. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. 2.Cold Runner. |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 1. 300,000-500,000 shots for 1 year under normal use prodcedure for pre-hardness steel material. 2. 5.00,000 shots for 1 year under normal use prodcedure for heat treatment steel material. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

製品フロー

金型をカスタマイズする方法は?

製品グループ : プラスチック射出成形金型 > プラスチック消費電子部品金型

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.